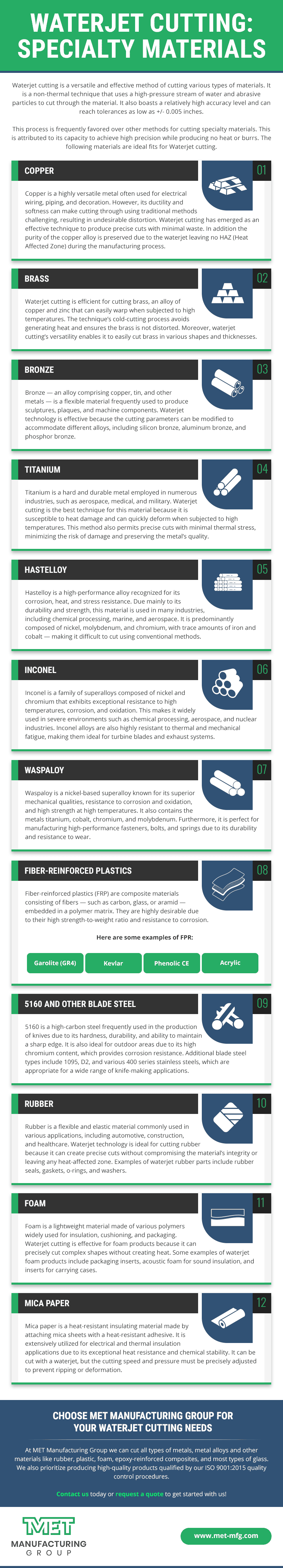

Waterjet Cutting: Specialty Materials

Waterjet cutting is a versatile and effective method of cutting various types of materials. It is a non-thermal technique that uses a high-pressure stream of water and abrasive particles to cut through the material. It also boasts a relatively high accuracy level and can reach tolerances as low as +/- 0.005 inches.

This process is frequently favored over other methods for cutting specialty materials. This is attributed to its capacity to achieve high precision while producing no heat or burrs. The following materials are ideal fits for Waterjet cutting.

1. Copper

Copper is a highly versatile metal often used for electrical wiring, piping, and decoration. However, its ductility and softness can make cutting through using traditional methods challenging, resulting in undesirable distortion. Waterjet cutting has emerged as an effective technique to produce precise cuts with minimal waste. In addition the purity of the copper alloy is preserved due to the waterjet leaving no HAZ (Heat Affected Zone) during the manufacturing process.

2. Brass

Waterjet cutting is efficient for cutting brass, an alloy of copper and zinc that can easily warp when subjected to high temperatures. The technique’s cold-cutting process avoids generating heat and ensures the brass is not distorted. Moreover, waterjet cutting’s versatility enables it to easily cut brass in various shapes and thicknesses.

3. Bronze

Bronze — an alloy comprising copper, tin, and other metals — is a flexible material frequently used to produce sculptures, plaques, and machine components. Waterjet technology is effective because the cutting parameters can be modified to accommodate different alloys, including silicon bronze, aluminum bronze, and phosphor bronze.

4. Titanium

Titanium is a hard and durable metal employed in numerous industries, such as aerospace, medical, and military. Waterjet cutting is the best technique for this material because it is susceptible to heat damage and can quickly deform when subjected to high temperatures. This method also permits precise cuts with minimal thermal stress, minimizing the risk of damage and preserving the metal’s quality.

5. Hastelloy

Hastelloy is a high-performance alloy recognized for its corrosion, heat, and stress resistance. Due mainly to its durability and strength, this material is used in many industries, including chemical processing, marine, and aerospace. It is predominantly composed of nickel, molybdenum, and chromium, with trace amounts of iron and cobalt — making it difficult to cut using conventional methods.

6. Inconel

Inconel is a family of superalloys composed of nickel and chromium that exhibits exceptional resistance to high temperatures, corrosion, and oxidation. This makes it widely used in severe environments such as chemical processing, aerospace, and nuclear industries. Inconel alloys are also highly resistant to thermal and mechanical fatigue, making them ideal for turbine blades and exhaust systems.

7. Waspaloy

Waspaloy is a nickel-based superalloy known for its superior mechanical qualities, resistance to corrosion and oxidation, and high strength at high temperatures. It also contains the metals titanium, cobalt, chromium, and molybdenum. Furthermore, it is perfect for manufacturing high-performance fasteners, bolts, and springs due to its durability and resistance to wear.

8. Fiber-Reinforced Plastics

Fiber-reinforced plastics (FRP) are composite materials consisting of fibers — such as carbon, glass, or aramid — embedded in a polymer matrix. They are highly desirable due to their high strength-to-weight ratio and resistance to corrosion.

Here are some examples of FPR:

- Garolite (GR4): This is made from layers of paper or fabric impregnated with a phenolic resin, known for its high strength.

- Kevlar: This is a high-strength synthetic fiber used in body armor, tires, and fiber optic cables.

- Phenolic CE: This is an industrial laminate made from layers of paper or fabric impregnated with a phenolic resin. It has a higher level of electrical conductivity than Garolite.

- Acrylic: This is a transparent thermoplastic material often used as a lightweight and shatter-resistant alternative to glass.

9. 5160 and Other Blade Steel

5160 is a high-carbon steel frequently used in the production of knives due to its hardness, durability, and ability to maintain a sharp edge. It is also ideal for outdoor areas due to its high chromium content, which provides corrosion resistance. Additional blade steel types include 1095, D2, and various 400 series stainless steels, which are appropriate for a wide range of knife-making applications.

10. Rubber

Rubber is a flexible and elastic material commonly used in various applications, including automotive, construction, and healthcare. Waterjet technology is ideal for cutting rubber because it can create precise cuts without compromising the material’s integrity or leaving any heat-affected zone. Examples of waterjet rubber parts include rubber seals, gaskets, o-rings, and washers.

11. Foam

Foam is a lightweight material made of various polymers widely used for insulation, cushioning, and packaging. Waterjet cutting is effective for foam products because it can precisely cut complex shapes without creating heat. Some examples of waterjet foam products include packaging inserts, acoustic foam for sound insulation, and inserts for carrying cases.

12. Mica Paper

Mica paper is a heat-resistant insulating material made by attaching mica sheets with a heat-resistant adhesive. It is extensively utilized for electrical and thermal insulation applications due to its exceptional heat resistance and chemical stability. It can be cut with a waterjet, but the cutting speed and pressure must be precisely adjusted to prevent ripping or deformation.

Choose MET Manufacturing Group for Your Waterjet Cutting Needs

At MET Manufacturing Group we can cut all types of metals, metal alloys and other materials like rubber, plastic, foam, epoxy-reinforced composites, and most types of glass. We also prioritize producing high-quality products qualified by our ISO 9001:2015 quality control procedures.

Contact us today or request a quote to get started with us!