Look around you. Almost every electronic device, automotive part, or medical instrument contains some small metal part. To create a part with such detail, manufacturers have a library of processes to use, but photochemical etching is a favorite. This is a process renowned for its precision and versatility. At MET Manufacturing Group, this advanced technique is just one of the techniques we use in our mission to deliver detailed parts for industries ranging from aerospace to healthcare to technology and beyond.

The photochemical etching process transforms sheet metal into a highly engineered part, and this article will show you how.

How Photochemical Etching Works: Step-By-Step Breakdown

1. Material Preparation

The journey begins with preparing the metal sheet. MET selects the ideal material—like stainless steel, copper, or nickel—based on the part’s purpose. The sheet is then cleaned to remove oils, dust, and other contaminants.

This cleaning step is vital. If any residue remains, the next step won’t work properly, and the whole product will suffer.

2. Photoresist Application

Next, a thin, light-sensitive polymer called photoresist is applied to both sides of the cleaned metal sheet. The photoresist is essentially a mask that will protect only specific areas of the sheet during the etching stage. These areas stay protected so the rest of the material can be exposed to the etchant.

3. Exposure and Development

Now, we align a precisely-designed photo-tool (a mylar film with the detailed pattern of the part in light resistant silver ink) onto the photoresist-coated sheet. The assembly is exposed to ultraviolet (UV) light. UV light hardens the photoresist wherever the metal is to be protected, while areas left unexposed stay soft.

After exposure, the metal sheet undergoes chemical development, often with an alkaline solution. This washes away the unhardened photoresist, revealing bare metal in the areas to be etched while leaving the hardened photoresist in place. This process ensures only the intended sections of metal are targeted for removal.

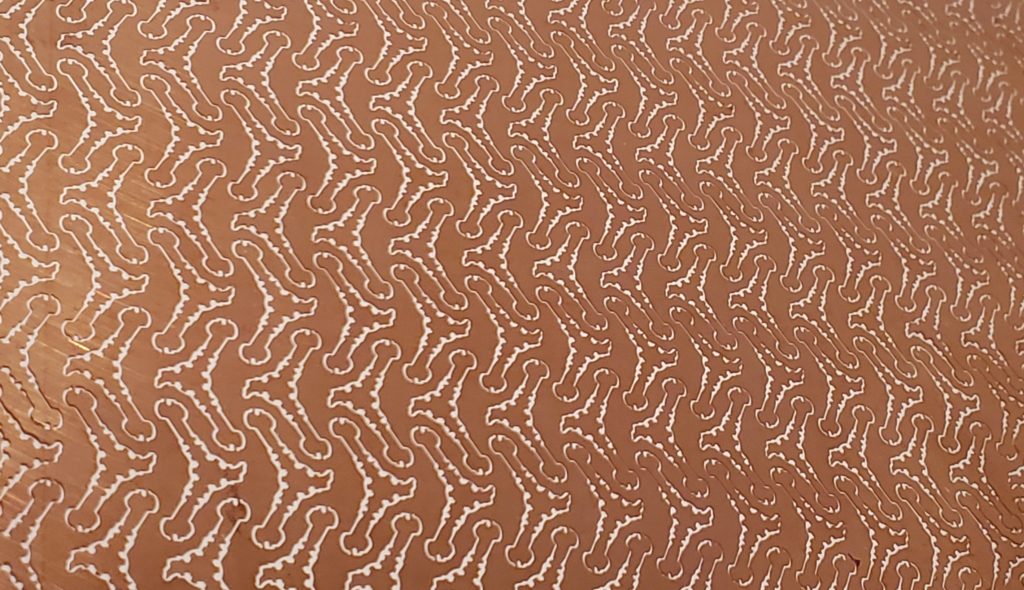

4. Etching: The Heart of the Process

In the core etching step, the prepared sheet passes through an etching machine. Here, a heated chemical solution, usually ferric chloride, is sprayed at high pressure onto both sides of the metal. The etchant dissolves the exposed metal, carving out the design and leaving the protected features behind.

5. Stripping and Final Inspection

Once etching is complete, the remaining photoresist is stripped away. What remains is the finished part, free from unwanted metal and ready for inspection. The quality control team then performs visual and dimensional checks to verify each part meets the required specifications.

Why Choose Photochemical Etching? Key Advantages

MET Manufacturing Group’s photochemical etching process offers exclusive benefits for manufacturers:

- Complex Geometries, Fast Turnaround: Cut intricate designs and tight tolerances (as fine as ±0.025mm or .001”) without tooling delays.

- No Mechanical Stresses: As a non-contact chemical process, photochemical etching preserves the metal’s properties and avoids burrs or deformation.

- Cost Efficiency: Digital photo-tools slash setup costs and allow for rapid prototyping and easy design revisions.

- Material Versatility: MET can etch stainless steel, copper alloys, brass, phosphorus bronze, exotic alloys like Kovar and Inconel and more, addressing diverse engineering needs and compliance requirements.

Applications Across Industries

- Electronics: From EMI shields to precision springs and connectors.

- Medical Devices: Surgical blades, stents, and microfluidics rely on burr-free, biocompatible etched parts.

- Aerospace: Lightweight sensors and intricate mesh filters, vital for flight safety and performance.

- Automotive: High-performance filtration meshes and identification nameplates.

These applications demonstrate how MET’s process empowers innovation in sectors where reliability, miniaturization, and precision are non-negotiable.

Take the Next Step with MET Manufacturing Group

Photochemical metal etching is an optimal solution for manufacturers seeking speed, precision, and cost control for complex metal components. MET Manufacturing Group’s expertise ensures your designs are manufactured with uncompromising quality, whether you need a prototype or a large production run.

Ready to see how MET’s photochemical etching can help meet your business goals? Explore MET’s step-by-step process or learn more about etching and fabrication services by contacting us. Let’s turn your ideas into reality with industry-leading precision!

![20250923_MET_RFQCTA-01 | MET Manufacturing Group, LLC Let’s Build Something Better Together! [Submit Your RFQ]](https://met-mfg.com/wp-content/uploads/20250923_MET_RFQCTA-01.png)

Comments are closed