CNC Routing for Non-Metallics: Precision Manufacturing with MET

Introduction to CNC Routing for Non-Metals

When your project demands precision cutting in plastics, wood, or foam, MET Manufacturing Group is your trusted partner. Since 1988, we’ve specialized in non-metal fabrication, driving innovation for industries such as electric vehicles, medical devices, aerospace, signage, construction, and more.

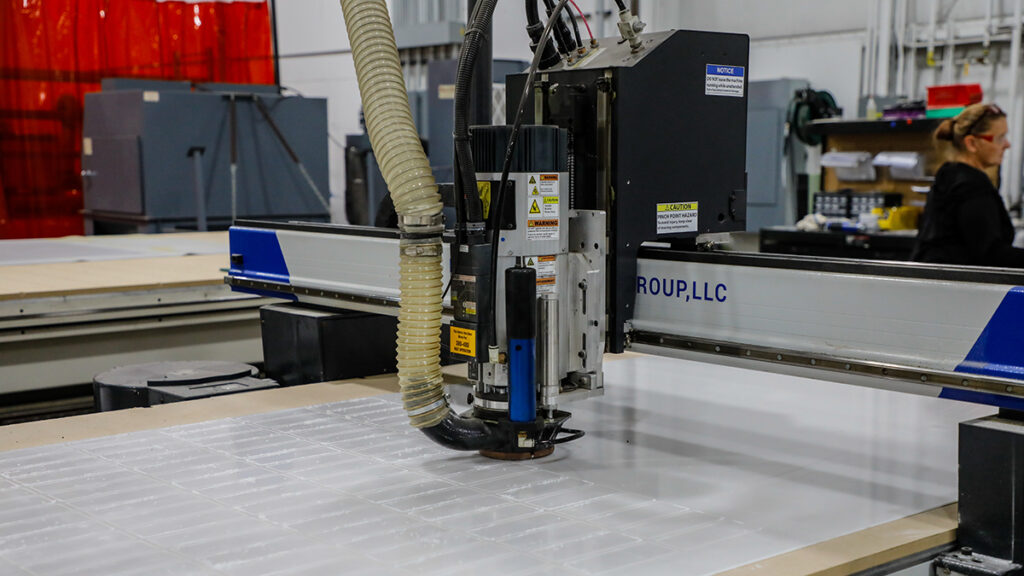

CNC routing is a computer-controlled process that delivers exceptional accuracy and repeatability, allowing us to create complex shapes and custom designs efficiently. Our clients rely on us for reliable, fast turnaround on prototypes and production runs. From intricate EV battery housing components to high-impact signage and specialty vehicle interiors, our experience spans a range of applications.

Are you searching for a solution for routed plastics, wood, or foam? Request a quote or contact our engineering team and bring your next idea to life with confidence.

How CNC Routing Works for Plastics, Wood, and Foam

MET leverages advanced CNC routing technology to handle a wide variety of non-metal sheet and block materials. The process starts with your digital design file, guiding our routers to create parts with unmatched precision through a fully automated, computer-controlled workflow. We manage every cut, curve, and contour to maximize material efficiency and ensure consistent quality from the first prototype to large production volumes.

Unlike manual fabrication or standard cutting, CNC routing enables scalable production, tight tolerances, and repeatability every time. We routinely create shapes that would be impossible or too costly with traditional woodworking or hand tooling. Our team assists from design collaboration to finished product, so even the most complex components and rapid prototyping needs are met—on your timeline.

Learn about our process or browse our project gallery for real-world examples.

Materials Commonly Routed by MET

At MET, we work with a broad spectrum of plastics (ABS, acrylic, polycarbonate, PETG, and more), engineered woods (such as plywood and MDF), and technical foams to match your unique specifications. Our expertise ensures proper material selection, whether your job requires flame-resistance for electronics, light weight for aerospace, or visual appeal for signage.

We cut everything from thick plastics for industrial housings to intricate wood panels for architectural work and custom foam for packaging or insulation. Rest assured, MET manages projects at varying scales and thicknesses—delivering both one-off prototypes and high-volume runs. Unsure which material best fits your needs?

Meet our engineering team or visit our material data pages to compare options and see example projects across key industries.

WOOD

Furniture – tables, chairs, cabinets, shelves

Cabinetry – kitchen and bathroom cabinets, doors, drawer fronts

Architectural millwork – crown molding, baseboards, panels, trims

Wooden signs – engraved business or decorative signs

Decorative wall art – carved designs, 3D reliefs

Musical instruments – guitar bodies, speaker enclosures

Toys and puzzles – wooden toys, brain teasers, educational tools

FOAM

Packaging inserts – custom-fit foam for tool kits, electronics

Theatrical props – sculptures, set decorations

Architectural mock-ups – models of buildings or interiors

Signage – large 3D letters or logos

Costume components – cosplay or movie production parts

PLASTIC

Signage – indoor/outdoor signs, channel letters, illuminated signs

Displays – point-of-sale (POS) displays, exhibition stands

Machine parts – custom brackets, covers, jigs, fixtures

Enclosures – electrical enclosures, housings for electronics

Prototypes – functional plastic parts for testing or mock-ups

Protective panels – guards for machines or tools

Engraved panels – control panels with labels and indicators

MISC

Countertops – custom shapes in Corian or other solid surfaces

Aircraft and automotive parts – from carbon fiber or FR4

Insulating panels – for electronics or high-temperature uses

Cutting boards – high-durability, precision-shaped

Router templates – for woodworking or metal routing

MET’s CNC Routing Capabilities and Services

Since 1988, MET Manufacturing Group has delivered industry-leading capabilities in CNC routing for plastic, wood, and foam. Our services go beyond just cutting—we offer integrated hardware insertion, assembly, finishing, custom painting, laser marking, packaging, and rapid prototyping, streamlining your project from start to finish. Our experienced engineers collaborate with you to optimize decisions and accelerate design cycles.

When you need scalability, quick turnarounds, or tailored engineering support, MET’s precision and reliability make the difference. Whether it’s a custom protective case, display components, or large-scale signage, our team is ready to deliver. Contact us for fast advice or request your custom quote today.

Advantages of CNC Routing for Non-Metallic Parts

CNC routing offers unparalleled advantages for plastics, wood, and foam: precision and repeatability, cost-effective prototyping, and smooth transition to full production. By using automated digital controls, we minimize waste and maximize consistency—saving time and resources for every client. This method is versatile, handling everything from architectural mock-ups to durable medical components and unique retail signage.

Our process fits both small batches and large orders, delivering value across industries. As one satisfied electronics client shared, “MET’s precision and fast turnaround helped us launch ahead of schedule.” With every project, you benefit from expertise, quality, and on-time delivery. Ready to unlock the potential of CNC-routed non-metals? Contact our experts or explore our product gallery to get started.

![20250923_MET_RFQCTA-01 | MET Manufacturing Group, LLC Let’s Build Something Better Together! [Submit Your RFQ]](https://met-mfg.com/wp-content/uploads/20250923_MET_RFQCTA-01.png)