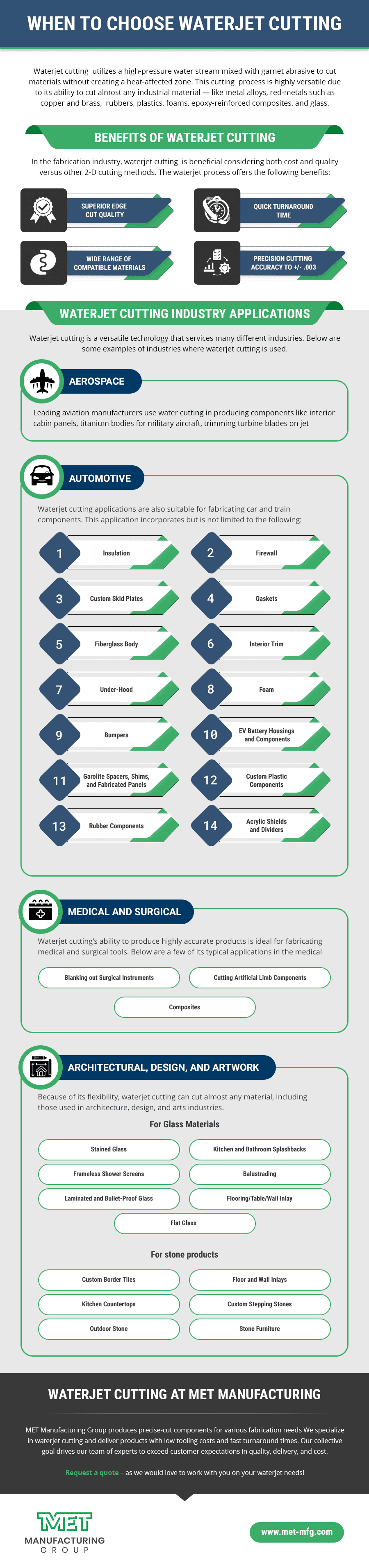

When To Choose Waterjet Cutting

Leave a CommentWaterjet cutting utilizes a high-pressure water stream mixed with garnet abrasive to cut materials without creating a heat-affected zone. This cutting process is highly versatile due to its ability to cut almost any industrial material — like metal alloys, red-metals such as copper and brass, rubbers, plastics, foams, epoxy-reinforced composites, and glass.

Benefits of Using Waterjet Cutting

In the fabrication industry, waterjet cutting is beneficial considering both cost and quality versus other 2-D cutting methods. The waterjet process offers the following benefits:

Superior Edge Cut Quality

Due to its high-pressure capabilities, waterjet cutting is more suitable than laser cutting for thicker, tough-to-cut materials. Waterjet cutting can easily cut through thick, dense metal up to 8” thick by applying pressure of up 60,000 PSI.

Waterjet cutting is also so beneficial when processing softer red metals and other materials that would melt in a laser cutting application. Materials such as copper, brass, plastic, gasket materials, and rubber are prime candidates to be processed using waterjet cutting.

Quick Turnaround Time

Waterjet cutting is a CNC process that allows a customer to provide a .DXF or CAD file to be waterjet cut quickly. Importing the file into our layout software allows for quick engineering to the cutting process. Lead times as little as 48 hours can be attained when working with waterjet cutting prototype applications.

Wide Range of Compatible Materials

CompatibleMaterials include Hastelloy, titanium, Inconel, hardened tool steels, copper, brass, gasket materials, rubber, steel, granite, plastic, garolite, and more.

Wide Range of Processing Ability

Unlike traditional cutting methods, the waterjet technique provides a wide range of options in cutting materials of diverse thicknesses. As a result, this process is ideal for thicker, heavier sheet metal applications, ranging from 1/4″ to 4″ thick in steel, aluminum, or stainless steel. However, the versatility of a waterjet also allows for thinner materials to be processed as well, starting at .020” thickness.

Waterjet Cutting Industry Applications

Waterjet cutting is a versatile technology that services many different industries. Below are some examples of industries where waterjet cutting is used.

Aerospace

Leading aviation manufacturers use water cutting in producing components like interior cabin panels, titanium bodies for military aircraft, trimming turbine blades on jet engines, and other aluminum body parts.

Automotive

Waterjet cutting applications are also suitable for fabricating car and train components. This application incorporates but is not limited to the following:

- Insulation

- Firewall

- Custom skid plates

- Gaskets

- Fiberglass body

- Interior trim

- Under-hood

- Foam

- Bumpers

- EV Battery Housings and Components

- Garolite spacers, shims, and fabricated panels

- Custom plastic components

- Rubber components

- Acrylic shields and dividers

Medical and Surgical

Waterjet cutting’s ability to produce highly accurate products is ideal for fabricating medical and surgical tools. Below are a few of its typical applications in the medical sector:

- Blanking out surgical instruments

- Cutting artificial limb components

- Composites

Architectural, Design, and Artwork

Because of its flexibility, waterjet cutting can cut almost any material, including those used in architecture, design, and arts industries.

For glass materials:

- Stained glass

- Kitchen and bathroom splashbacks

- Frameless shower screens

- Balustrading

- Laminated and bullet-proof glass

- Flooring/table/wall inlay

- Flat glass

For stone products:

- Custom border tiles

- Floor and wall inlays

- Kitchen countertops

- Custom stepping stones

- Outdoor stone

- Stone furniture

Waterjet Cutting at MET Manufacturing

MET Manufacturing Group produces precise-cut components for various fabrication needs We specialize in waterjet cutting and deliver products with low tooling costs and fast turnaround times. Our collective goal drives our team of experts to exceed customer expectations in quality, delivery, and cost.

Request a quote – as we would love to work with you on your waterjet needs!