Manual and Robotic Welding Services at MET Manufacturing

Introduction to Our Welding Services

At MET Manufacturing Group, precision metal fabrication and welding have been our benchmark since 1988. Our reputation stands on decades of delivering high-quality service and unwavering commitment to our clients’ success.

MET combines the expert hands of skilled welders with the cutting-edge speed and repeatability of robotic welding, offering versatile solutions for projects of all shapes and sizes. As an ISO 9001:2015 certified and RoHS-compliant manufacturer, we seek to provide stress-free applications, precise tolerances, and reliable results for the most complex designs. Whether your job calls for a custom, hands-on approach or high-volume, automated consistency, MET Manufacturing is your trusted partner for welding excellence.

Manual Welding Capabilities

Some projects require the human touch. That’s why MET’s manual welding technicians deliver artisan-level precision on applications like custom prototyping, specialty repairs, and small batch runs.

Powered by two Lincoln Powerwave 300c welders, we can weld anything aluminum or steel. Even stainless steel is no problem for MET!

Our direct engineer engagement and hands-on testing ensure project managers receive the precision and accountability their operations demand. From prototypes for automotive brackets to critical aerospace assemblies with extremely tight tolerances, MET is up to the task.

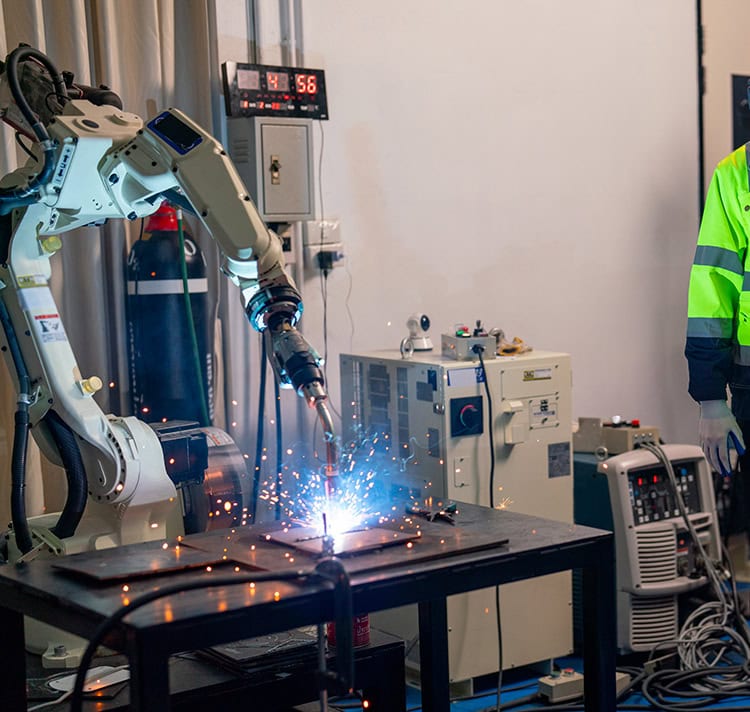

Robotic Welding Capabilities

When your project demands high-volume production, uniform quality, and fast turnaround, MET’s robotic welding services deliver. At the core of our automation lineup is the Lincoln Electric Cooper Welding Cobot: a state-of-the-art collaborative robotic system designed to work safely alongside our welding team.

This cobot merges the efficiency of automation with the flexibility of human collaboration, offering a unique balance for modern manufacturing needs. Its interface allows our technicians to set up complex welds in minutes and ensure consistent, repeatable results across every unit.

The result? Clients in automotive, electronics, and defense sectors benefit from reduced per-unit costs, enhanced product quality, and minimized material waste. Robotic welding is the answer for high-volume projects requiring identical results every time.

Materials & Industries Served

MET offers welding expertise across a wide range of metals: steel, aluminum and stainless steel. Our services support mission-critical projects in automotive, aerospace, medical devices, electronics, and military/defense industries.

From precision-welded medical device enclosures to rugged automotive components and military-grade assemblies, our solutions meet demanding standards for quality and durability.

![20250923_MET_RFQCTA-01 | MET Manufacturing Group, LLC Let’s Build Something Better Together! [Submit Your RFQ]](https://met-mfg.com/wp-content/uploads/20250923_MET_RFQCTA-01.png)