Laser Cutting Services at MET Manufacturing

Introduction to MET’s Laser Cutting Expertise

At MET Manufacturing, our legacy in precision metalworking sets the standard for modern metal fabrication. For over 35 years, engineers, project managers, and procurement specialists have relied on our team for fast, accurate, and dependable solutions. We leverage state-of-the-art technology, including our Mazak 7Kw Optiplex S7 Fiber Laser, to deliver the highest quality laser cutting services in the industry.

Laser cutting provides crisp, clean edges and detailed geometry, handling complex shapes with incredible speed. MET is proud to maintain ISO 9001:2015 certification and RoHS compliance, ensuring every product meets strict quality and safety requirements. Whether your project calls for prototypes, production runs, tight tolerances, or rapid turnarounds, our skilled staff and advanced equipment are dedicated to delivering results that keep your business ahead.

How Laser Cutting Works & Our Process

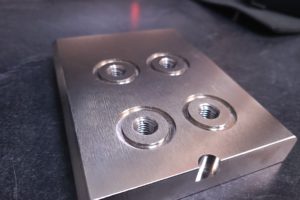

Laser cutting uses a powerful, focused beam of light to precisely slice through metals such as stainless steel, aluminum, and titanium. MET’s fiber laser technology outpaces other traditional flat cutting processes—like plasma cutting, CNC routing and punching, and carbon laser cutting – via faster cutting rates, superior edge quality, and minimizing heat distortion to protect the integrity of the base metal.

Here’s how our process works: You send us your design files (DXF, DWG, STEP, and most CAD formats accepted). Our digital nesting software ensures the most efficient use of your raw material, reducing costs and maximizing sustainability. We program the laser for your project’s exact specs, then carefully cut, inspect, and finish each part to your requirements. Material thicknesses range from thin sheets up to one inch, with dimensions suitable for miniature components or large-scale panels.

Materials Commonly Routed by MET

MET Manufacturing is equipped with the Mazak 7Kw Optiplex S7 Fiber Laser, one of the industry’s most advanced machines. This technology allows us to achieve exceptional speed, accuracy, and flexibility across a wide range of materials—including aluminum, stainless steel, carbon steel, titanium, copper, and brass.

From intricate prototypes to full-scale production runs, our laser cutting services are tailored for complex geometries, fine detail, and superior edge finishes. Supported part sizes reach up to 120” x 60” and thicknesses up to 1”, depending on material. We offer integrated services like forming, black oxide, finishing, assembly, and plating—helping customers streamline production from raw material to finished product.

Looking for support on custom projects? Collaborate with MET’s technical experts for optimal design and production solutions. Contact our team to get the best results for your next challenging application.

Industries Served & Applications

MET Manufacturing serves a wide range of industries where precision and reliability are critical — including automotive, specialty vehicles, marine, defense, and aerospace. Our laser cutting capabilities deliver high-performance metal components designed to meet the unique demands of each market.

For the automotive sector, we produce chassis brackets, engine components, shielding, and trim parts that help manufacturers accelerate development and ensure long-term durability. Specialty vehicle customers rely on us for heavy-duty structural parts and custom brackets that withstand rugged use. In marine applications, our corrosion-resistant laser-cut panels and mounts are engineered for reliability in harsh environments. Defense teams count on us for precision housings and protective components where performance is mission-critical. For aerospace, we deliver lightweight, tight-tolerance parts such as brackets and shielding that reduce weight while maintaining strength.

No matter the industry, our stress-free, tight-tolerance laser cutting process supports both rapid prototyping and scaled production, giving engineers the accuracy they need and purchasing teams the confidence of consistent quality, cost control, and on-time delivery.

Frequently Asked Questions

What metals do you laser cut?

We work with aluminum, stainless steel, carbon steel, titanium, copper, brass, and specialty alloys.

What file formats do you accept?

We accept DXF, DWG, STEP, and most standard CAD formats.

What are your max/min part dimensions and thicknesses?

Up to 120″ x 60″ and 1″ thick, depending on the metal.

What is the lead time for prototypes or production parts?

Turnaround times vary, but most projects are completed in 2–10 business days.

How does laser cutting compare to waterjet or etching?

Laser cutting offers faster turnaround, tighter tolerances, and reduced material waste.

![20250923_MET_RFQCTA-01 | MET Manufacturing Group, LLC Let’s Build Something Better Together! [Submit Your RFQ]](https://met-mfg.com/wp-content/uploads/20250923_MET_RFQCTA-01.png)