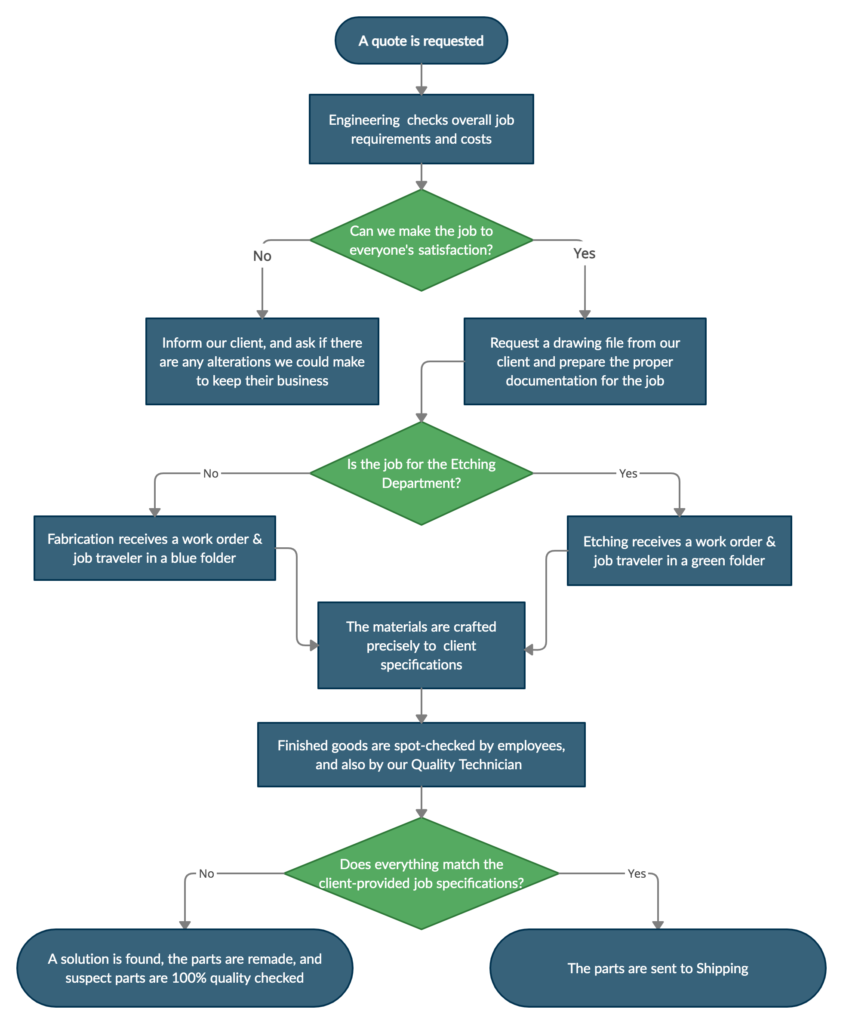

Our Policy

Maintaining a quality product is our top priority. With such tight tolerances and an array of different processes we must have high precision and repeatability for our products. For both the Fabrication and Etching departments we only use calibrated measurement devices.

Samples are taken during the creation of goods and checked using multiple criteria to make sure we meet the customers needs. If any irregularities are observed, we halt current progress and make adjustments to machinery or chemistry. Product that has already been created is thoroughly inspected to verify conformity to the job requirements.

After Fabrication and Etching are completed, the goods are sent through a quality control procedure by our dedicated Quality Technician. All dimensional tolerances and outside services are checked and confirmed. Only after both inspections and confirmation that our standards are met, can the product be shipped. Machines are regularly cleaned and inspected regularly to prevent inconsistency or downtime for repair.

RoHS Compliant | Made in the USA | ISO Certified 9001:2015